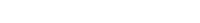

Fel-Pro’s new molded-rubber PermaDryPlus gasket line for valve covers and oil pans is designed for ease of installation and reliable sealing, even with multiple cycles on and off the engine.

“We use an in-house developed rubber compound,” says Fel-Pro’s Ron Rotunno. “It’s also resistant to caustic fluids.”

Fel-Pro valve-cover gaskets feature a rigid carrier made of aluminized steel or composite to resist high heat and vacuum. The silicone rubber sealing beads are precision edge-molded to compensate for surface irregularities. Other features include built-in torque limiters to help prevent over-tightening and over-compression of the gasket; locating tabs to assure proper alignment; and bolt-hole locks to help reduce installation time.

“The thicker material offers the added benefit of additional clearance for rocker arms,” adds Rotunno.

The rigid-carrier gaskets feature torque limiters and silicone rubber sealing beads. Water-outlet gaskets are also available.

The PermaDryPlus line of oil pan gaskets feature 1-piece construction and rigid carrier for improved alignment and fit. The pan gaskets come with snapups to hold the gasket in place for quicker installation.

“These gaskets should be installed dry, no RTV,” reminds Rotunno. “For the oil pan gaskets, you can apply just a small dab of RTV in the corners because the pans aren’t always square to the block.”

The PermaDryPlus line continues with a line of rigid carrier gaskets for water outlets and can help seal slightly warped or corroded thermostat housings. These gaskets feature the same construction designs and silicone rubber sealing beads.

All Fel-Pro gaskets are designed and manufactured in Skokie, Illinois. Applications range from OEM replacement to high-end engines for drag racing and stock cars.

Finally, check out the video below for more on the history of Fel-Pro gaskets. Did you know Fel-Pro started out manufacturing felt products, like horse blankets?