Running flat out for a mile is not for the faint of heart. Doing so in a 2,400-plus-horsepower vehicle is no joke either. When you are running 257 miles per hour in a barely streetable 2015 Mustang GT, it is a whole different level of daring and driver Allyn Watkins and his support squad at BoostWorks in Katy, Texas, have no intention of slowing down.

If you aren’t familiar with BoostWorks, the shop has been involved with a number of huge-power, big speed builds over the last several years. The outfit works on all makes and models, but has garnered good success with the latest Mustangs and power adders like the Kenne Bell line of superchargers and some custom turbo systems.

While the huge turbo inlets puncturing the MMR front fascia definitely let you know there is something aggressive going on underhood, you still might not suspect that Allyn Watkins’s BoostWorks-prepped 2015 Mustang GT cranks out well over 2,000 horsepower and flies down the Texas Mile at over 250 mph. (Photo Credit: BoostWorks)

“I think it’s a combination of things. Some of it is that we’ve always pushed to be the ‘first’ when new platforms come out; whether that be a speed record, or a turbo system, etc. The S550 has been one such platform for us, and the success from those ventures has been key for the growth of our company,” BoostWorks main man Travis Burelle told us. “That growth has attracted the type of folks who want to push the envelope and build these insane vehicles. The other factor is that we’ve amassed a total of 40 years of experience combined with our guys in the shop. All of us have roots in big-horsepower, cutting-edge stuff. So that always helps to build trust and a good portfolio of customers who want very fast vehicles.”

From Street To ‘Mile’

This particular project began as a Kenne Bell 4.7-liter Mammoth-boosted street beast that cranked out four-digit numbers courtesy of a Lund Racing custom calibration.

“He’s got good taste and allowed us to work without limits in regards to creative freedom and ideas; nothing was off limits,” Travis said of Allyn. “So, we sort of worked out a goal, and Allyn stood behind us 110 percent. He’s a hell of a driver as well, and he’s still learning the ropes. But, with a 1,000-plus-wheel-horsepower Fox and a 1,000-plus-wheel horsepower, twin-turbo GT350 (also a Boost Works build) as daily drivers, it shows that he’s about going fast; be it on the street, or on the track.”

From that point on, we turned out some mid-220-mph passes. — Travis Burelle, BoostWorks

However, when the car changed hands to its current owner and driver, Allyn Watkins, and more the move toward aggressively pursuing the Texas Mile Mustang record of 260 mph, the crew at BoostWorks created a custom turbo system based on a pair of Precision Turbos and controlled by an AEM standalone EFI controller.

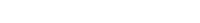

With the goal of making even more power and setting a new Mustang top-speed record, the BoostWorks team picked up a robust Coyote engine block from Bear Block Motors and shipped it the MPR Race Engines for a new dry-deck, dry sump build filled with top-shelf hardware like a Winberg crankshaft, Callies rods, and Diamond pistons. This short-block is topped by ported Shelby GT350 heads with custom cams and fed by a custom sheetmetal intake.

“From that point on, we turned out some mid-220-mph passes, but we all decided that a jump to turbochargers was necessary to get us into the competitive zone with the likes of M2K Motorsports, and AirTech of Houston,” Travis explained. “Those guys were running 260 mph in their GT500, and 290-plus mph in their GT. Allyn ended up purchasing the car from Jeff, and it was decided that the supercharger just wasn’t going to get us there. But, we had a lot of fun with Kenne Bell and we continue to work heavily with them at BoostWorks!”

Built Ford Tough

While this S550 is still on the edge of streetability, you can’t just throw over 45 pounds of boost at a stock engine for the full length of a mile and hope for it to live. While BoostWorks already had a fortified engine under the hood for the previous top-speed runs, the pursuit for more miles per hour necessitated an even stouter foundation based on a rugged aftermarket block.

It takes a team of folks working together to fix the flaws inherent to the Coyote platform. — Travis Burelle, BoostWorks

“Lots of prayers and VooDoo (no pun intended)! It takes a team of folks working together to fix the flaws inherent to the Coyote platform. The factory sleeves are the first concern, of course. Next up would be block rigidity and flexing around the engine mount bosses, in the valley, and movement in the caps. Movement in the deck is also a concern with head gasket failures being a big issue,” Travis said of what it takes for a modern 5.0 to survive in this environment. “Bear Block Motors addressed all of these issues, and more, with its aftermarket Coyote casting. The company took feedback from racers, and made revisions where necessary. The result is a block that’s has a closed deck, thicker main webbing, doweled main caps, ½-inch studs, thicker pan rails, webbing in the valley, webbing around the engine mount bosses, and a host of other features.”

You would imagine running out of boost with two Precision 7225 turbos boosting a race-prepped Coyote engine, that’s just what happened with this car. The turbos hit the wall at 45 pounds of boost, so BoosWorks is upgrading to billet, ball-bearing Precision 8385 turbos for an all-out assault on the Texas Mile this March.

To make the most of that robust block, BoostWorks turned to one of the leading Coyote builders in the country to fill it with a host of top-quality hardware designed to live in the harshest of environs.

“Tim Eichorn at MPR Engines in Florida did extensive work to the block by adding O-rings on the deck, machining the inside of the block to accept a billet crankshaft from Winberg, and a few other tricks that we’ll keep close to the vest,” Travis added. “Diamond pistons, and Callies 300m billet rods finish off the bottom end, and the engine remains wet sump. Topped off with worked over GT350 cylinder head castings, MPR’s valvetrain/camshaft package, and their fresh billet coil covers, it’s a work of art and a testament to just how much the aftermarket industry has embraced the Coyote platform. Our test engine has held up well so far!”

Under New Management

Controlling that built engine will be the aforementioned AEM Infinity 7-Series stand-alone management, paired with an CD7 Digital Dash, provides the sort of fast, finite control needed to not only create consistent power, but also apply it to the pavement.

“Lund Racing has done a really great job at utilizing the factory PCM on some very fast cars, including many coming out of our stable. But, at 2,300 to 2,400 horsepower, we’re far past the limitations of the stock PCM. There are several key features that really stand out for us when you look at the advantages. The biggest feature is the ability to build and employ a very nice traction control strategy. We can pull boost or timing to control wheelspin, and that’s critical when you’re trying to go down a runway that’s unprepped for any sort of racing. AEM’s traction control flexibility is very nice!”

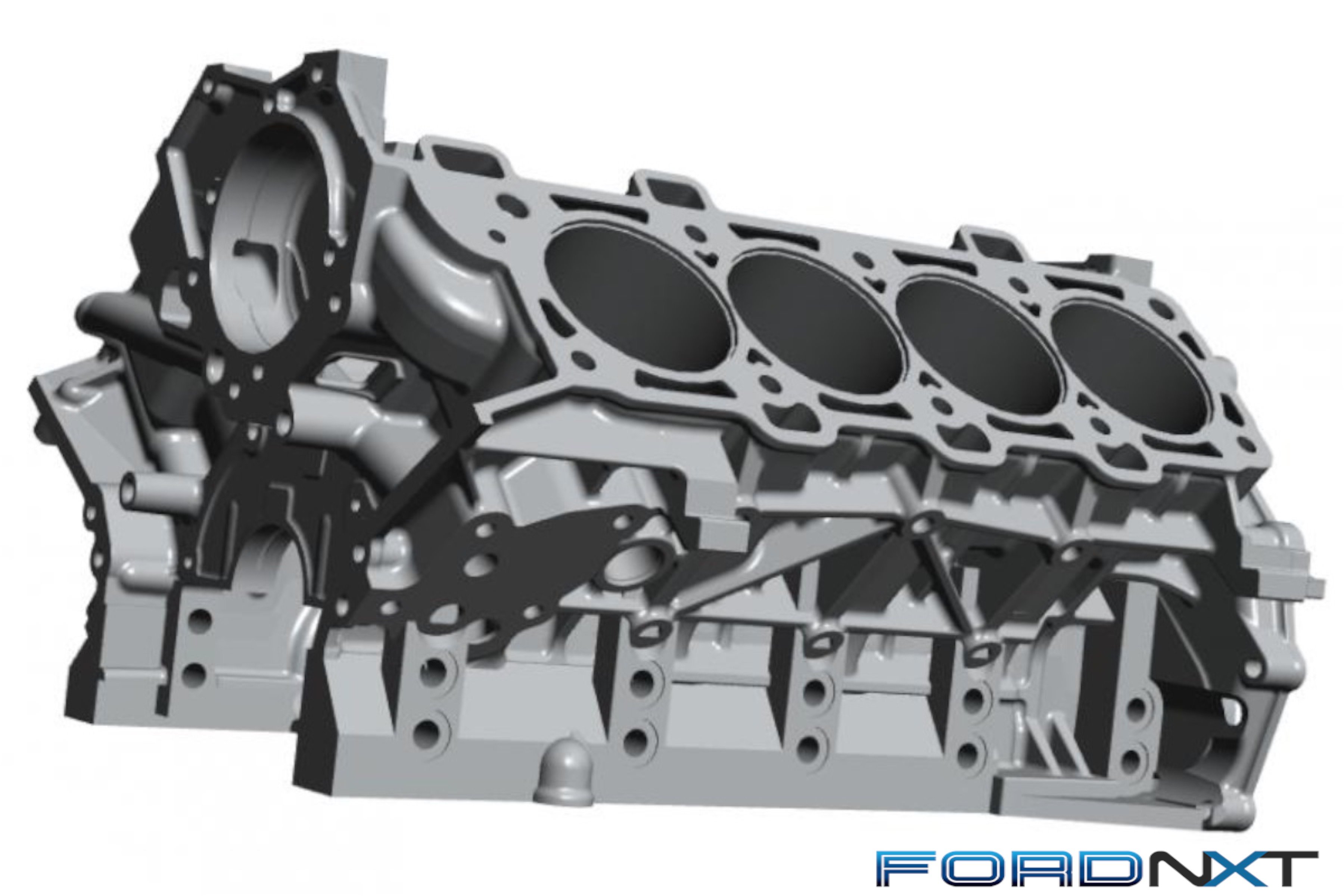

As you might imagine, feeding a 2,400-plus-horsepower turbo Coyote requires a river of race fuel, which BoostWorks supplied via a massive custom fuel system. “The car runs on Ignite 114 (90-percent ethanol). It burns about 3 gallons of fuel in the 22-23 seconds that it takes to cover the mile,” Travis said. “A pair of Magnafuel 2,500-horsepower-capable pumps, fed by twin -12AN lines from a custom 9-gallon fuel cell push fuel up to the front of the vehicle where it is distributed to eight Bosch 1,000cc injectors for primary fueling, and eight Denso 2,700cc injectors, which provide the grunt at 45-50 psi of boost.”

AEM’s EFI system is more than just boost control, however. It delivers the kind of control over fuel, timing, and boost that the factory PCM could only dream of offering. Of course, the factory gear was never expected to harness a mid-2,000-horsepower turbo engine.

If there’s any variance, the 7-series PCM has one of the fastest processors of any standalone on the market. — Travis Burelle, BoostWorks

“Another feature that’s very nice is the ability to run in closed-loop fueling all the time. If there’s any variance, the 7-series PCM has one of the fastest processors of any standalone on the market, and can easily make very quick adjustments on the fly to compensate (within a window of course),” Travis added. “It gives a degree of confidence and failsafe. Boost control is built in, and it’s very precise. We typically hold boost to within a tenth of a pound of what we’re commanding, which is always helpful since it doesn’t over- or under-shoot the target. Aaron Miller at Nth Moto was trackside with us, and was a huge help getting us to where we are today. His experience with AEM and tuning in general is a huge addition to our team!”

By Air And By Land

In all, this combination is setting up to challenge that 260-mph record. However, traveling at those kind of speeds requires paying attention to the aerodynamics. While BoostWorks has done well in this regard, upgrading the body parts using more intuition than science.

It’s still a brick, but the S550 has a drag coefficient that’s 4 percent better than the previous S197 chassis. — Travis Burelle, BoostWorks

“It’s still a brick, but the S550 has a drag coefficient that’s 4 percent better than the previous S197 chassis. At 250-plus mph, that starts to add up to a noticeable increase in efficiency/mph. Without the advantage of CFD modeling or a wind tunnel, we’re really at a disadvantage whenever we make decisions on aerodynamic mods,” Travis confessed. “So, it’s kind of a commonsense approach at this point: Keep the rake/angle of attack pretty steep, and keep the front end low to the ground. A custom ¼-inch-thick, 6061 belly pan goes back to the oil pan, and a completely closed off from bumper keeps air from getting into the engine bay. This prevents lift and keeps the car firmly planted. Big spring rates keep it from turning into a snowplow as the downforce increases on the nose at speed. The MMR wing, and a modified GT350 rear diffuser/belly pan, plus valance/bumper cleans up the air coming off of the car. This is an area where you can really pick up speed by cleaning up the air out back. BMR’s suspension and sway bars make for a rock-solid ride, as there is very little drama going downtrack.”

When you are trying to supply over 45 pounds of boost to a race-built Coyote engine, an off-the-shelf intake is not in the cards. BoostWorks commissioned a G1Pro custom sheetmetal intake manifold atop a 2,500-horsepower Bell air-to-water aftercooler core, which helps tame the inlet temperatures during a flat-out run.

Using some well-chosen upgrades on the body, and bolting on off-the-shelf upgrades from BMR Suspension have resulted in an amazingly docile and controllable at such warp speeds. Setting up cars like this walks the line between a straight-line drag car and a corner-carving road racer.

Record-Setting Combo

• AEM Infinity 7-Series standalone engine management (tuned track-side by Aaron Miller of Nth Moto) w/ CD7 Digital Dash and data acquisition

• AEM GPS telemetry and gyro/accelerometer

• AEM individual-cylinder lambda for full sequential tuning

• BMR Suspension front sway bar, rear sway bar, springs, and IRS reinforcements

• BoostWorks 25-gallon intercooler tank w/ 12.5-gallon cold side and 12.5-gallon hot-side return

• BoostWorks custom turbo system w/ 321 stainless 2-inch primaries, 321 stainless 3-inch secondaries, and bumper exit, 4.5-inch downpipes

• Callies 300m billet rods

• Dailey Engineering dry-sump and dry deck

• Diamond custom pistons

• G1Pro custom sheet metal intake manifold w/ 2500-horsepower Bell air-to-water core

• JW Performance-built TH400 transmission w/ 4.5-inch gForce custom driveshaft

• Koni Yellow dampers

• MMR modified carbon front bumper and carbon rear wing

• MPR custom camshafts

• MRR wheels fitted with Hoosier R7 road-race slicks

• O-ringed Bear Block Motors Coyote block built by MPR Racing Engines

• Precision 66mm wastegates w/ 2.5-inch bumper exit dump tubes

• Shelby GT350 Voodoo cylinder heads

• Stroud Safety custom parachute, and fire suppression system

• Two Magnafuel Pro Series 2,500-horsepower fuel pumps w/ twin -12 feeds and custom fuel cell mounted in the driver-side OEM fuel tank location and factory fill

• Two billet, ball-bearing Precision 8385 turbochargers

• Weir Racing gForce 9-inch independent rear suspension conversion w/ 2.73 gears from ’70s Lincoln

• Winberg forged crankshaft

“In some ways, it’s similar, but in a lot of ways it’s much different. A drag or road racer would be looking to lighten up the vehicle as much as possible, while we look more at adding weight strategically to give us the most stability at sustained high speeds where aero can play some very dirty tricks on you. Also, the drag racer may be looking for maximum traction for the first couple hundred feet (where most drag races are won/lost), whereas the mile car looks like it’s leaving the line for a Sunday stroll,” Travis said. “We rely heavily on traction control to manage power, but we often can’t ramp in 2,000-plus horsepower until after the half-mile mark. So, it’s the same end goal, but much different strategies. Suspension-wise, it’s actually very similar — in terms of dampeners, sway bars, etc. — to a road-race car. The spring rates are usually much higher on the mile car though, as we see thousands of pounds of downforce. The angle of attack is much more aggressive as well to help reduce lift.”

Goal-Oriented

As the team pushes toward its next top-speed goal, Boost Works is adding a set of larger turbos to properly feed the MPR-prepped, Bear Block Coyote.

“The car currently makes around 2,300 to 2,400 horsepower. That’s not enough. We’re swapping from Precision 7175s to 8385s, and going to a 2-inch primary/3-inch collector/secondary pre-turbine housing. The downpipe diameter will increase from 3.5 to 4.5 inches as well. The turbine housings will get a bump as well, going from .81 A/R to .98 A/R. We’re working with Dailey Engineering to get a dry-sump system in place on the engine as well, since the wet sump is at its limits at 9,000-plus rpm,” Travis said. “Tim at MPR is also going to go ahead and dry-deck the engine (eliminating the transfer of coolant between head and block through the deck). Replaced with external lines to transfer coolant, we can ditch the MLS gaskets for a set of copper gaskets with a much larger O-ring. This will give us good sealing in the event that we reach the limit of the 12mm head studs.”

With a revamped drivetrain and improved safety, this sleek S550 will strive to not only set a record, but it handily. It won’t be an easy task, but this team seems pretty determined.

Allyn Watkins is supported Travis Burrelle (middle), Joshua Hebert, Andrew Bierig, Nicholas Thompson, and James Goertz of BoostWorks. Combined, this crew helped create the fastest 2015-plus Mustang on the planet and they hope to get faster and broaden that record this spring.

“The car is also going from a 10-point cage, to a full 25.3-certified funny car cage. Grumpy’s Garage in Houston is tackling that job. We intend to be back at the Texas Mile in late March. The current overall Mustang record is held by Bill Wagner/M2K Motorsports in their GT500 at 260 mph,” Travis added. “While we hold the S550 chassis record, we do plan on competing for the overall record as well. Bill’s car has a lot left in it, and those guys are capable of going much faster, so we realize that we have a tall task ahead of us. We’ll see how it pans out, but I think 270 mph is an attainable number if the car remains stable at those speeds.”

Stay tuned as this team heads to the Texas Mile on March 23-25, 2018 to make what it hopes is the run heard ’round the Mustang world.