Setting a correct throwout bearing clearance is not difficult but it’s mighty important to prevent premature wear of your clutch, no matter if you drive a performance car, hot rod or muscle car. That’s why the COMP Performance Group has stepped up and created an easy to follow video guide showing you exactly how to set the proper throwout bearing clearance for any application. Check it out above.

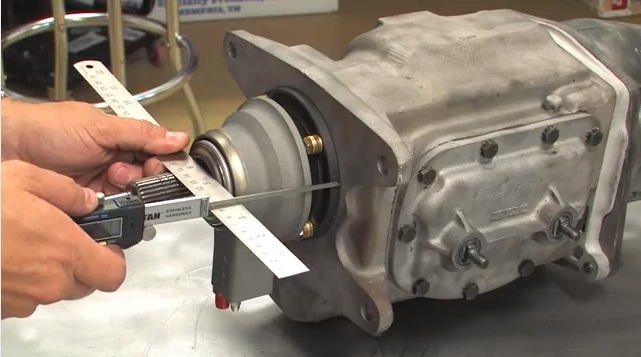

In order to properly set your throwout bearing clearance, you need to have everything installed like it would be in final assembly.

Clutches come in all different forms, from light-weight to performance and even race-specific, but no matter how hardy your clutch is designed to be, an improper throwout bearing clearance will shorten its life. Surprisingly, something so important to your clutch’s functionality and life span is not hard to set yourself in or out of the engine bay.

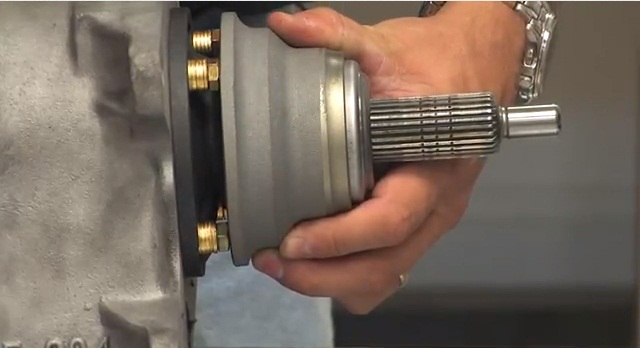

To set your throwout bearing clearance properly, you must start by installing everything as it will be upon final assembly, from the clutch to the bell housing and even the midplate for racing applications.

From there you can either use a support rail like the one offered by COMP’s Quarter Master brand, or just use the washers that come with the throwout bearing to adjust the depth of the bolts the bearing will be setting against.

To position your throwout bearing properly, you can either opt to use a support rail or washers to adjust the depth of the bolts the bearing will be sitting on.

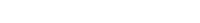

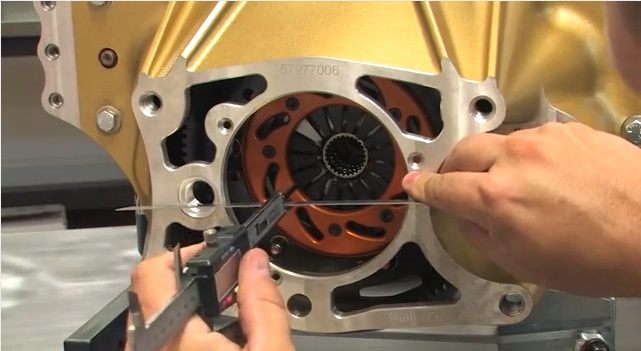

Accurate measurements are important when setting your throwout bearing clearance, so COMP recommends using digital or dial calipers, as well as a straight edge to make sure every measurement is as accurate as possible.

With the throwout bearing in place, a measurement needs to be taken from the center of the bell housing opening to the edge of one of the clutch fingers.

Then with the release bearing fully compressed and in place, another measurement needs to be taken from the end of the release bearing to the transmission face. Instructions on how to take these measurements are included in the video.

Once these measurements have been taken, you can calculate your throwout bearing clearance. All you have to do is take your release bearing to transmission face measurement and subtract it from the bell housing to clutch finger opening measurement. This is your current throwout bearing clearance.

Accuracy is key, so COMP recommends a proper set of tools and taking measurements more than once to be certain of your numbers.

Setting a proper throwout bearing clearance can seem like a daunting task but with the help of COMP’s easy to follow video, you’ll have yours set in no time.